Our Services

Building a Foundation of Strength and Precision

Our civil and construction division provides comprehensive project support, from initial site preparation to final commissioning. We specialize in transforming raw land into resilient industrial facilities and infrastructure.

Our process ensures a seamless journey:

- Site Preparation

We conduct thorough clearing, grading, and leveling to create a stable foundation for construction activities, ensuring project integrity from day one.

- Structural Design & Engineering

Our experts develop detailed structural plans and calculations, guaranteeing the stability and longevity of all buildings and infrastructure.

- Building Construction

Execution of all construction activities, including foundation laying, framing, roofing, and finishing works, adhering strictly to the highest industry standards and client specifications.

- Renovation & Rehabilitation

Upgrading and refurbishing existing structures to enhance functionality, aesthetics, and essential safety requirements

- Project Management

Efficient coordination of resources, rigorous scheduling, and meticulous budgeting ensure timely completion and cost-effective delivery of complex projects.

Precision Installation for Peak Performance

Our installation methodology:

- Site Preparation

We ensure proper site readiness, including clearing space, leveling surfaces, and guaranteeing robust access points for heavy machinery before installation begins.

- Rigging and Hoisting

Utilizing specialized rigging equipment and techniques, we safely lift and position heavy machinery into place, following rigorous safety protocols to mitigate all risks.

- Assembly and Alignment

Once positioned, our technicians proceed with meticulous assembly and alignment, adhering to exact engineering specifications crucial for optimal performance and equipment longevity.

- Integration and Testing

Post-installation, we integrate equipment with existing systems and conduct thorough testing to verify functionality, performance, and compliance with all operational requirements.

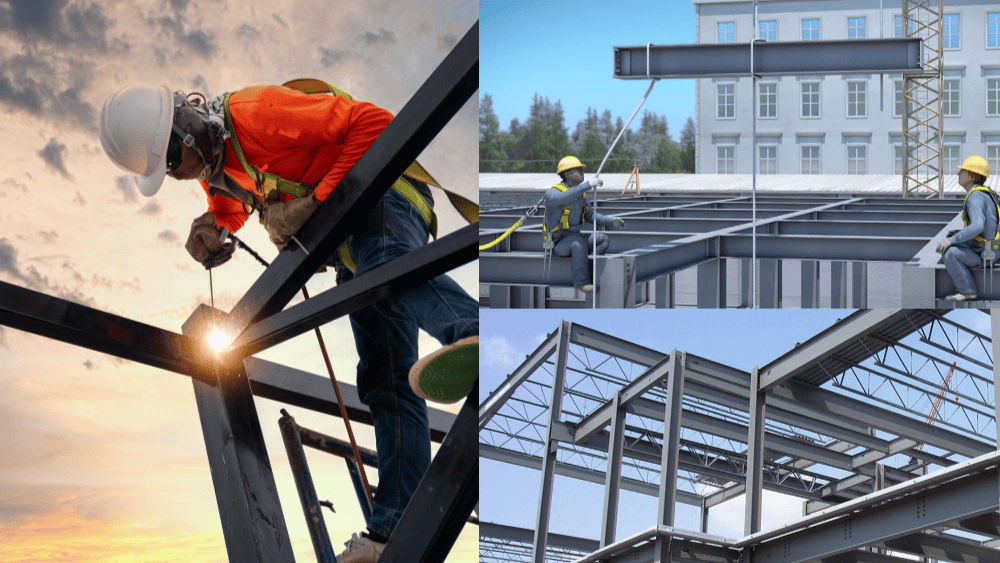

Engineered Steel Solutions for Industrial Demands

Our fabrication and erection process:

- Fabrication

Our skilled team utilizes advanced techniques and equipment to fabricate high-quality steel components, from structural beams and columns to customized metalwork, ensuring precision and durability

- Erection

Our expertise in steel erection ensures efficient and safe installation, adhering strictly to all industry standards and project specifications.

Reliable Piping Systems for Seamless Operations

Our piping solutions include:

- Custom Fabrication

We specialize in custom pipe fabrication using quality materials and precise techniques to meet bespoke project requirements for process piping, utility lines, and specialized installations.

- Expert Erection

Our experienced teams manage the entire installation lifecycle, delivering reliable solutions that optimize efficiency, guarantee seamless operations, and ensure long-lasting reliability.

Powering and Controlling Industrial Facilities

Our E&I services cover:

- Installation & Optimization

Our skilled technicians and engineers handle the installation, maintenance, and optimization of complex electrical systems and instrumentation equipment.

- Specialization

We specialize in power distribution, control systems, lighting, and instrumentation integration, ensuring full compliance with safety standards and peak operational efficiency from project conception to final commissioning

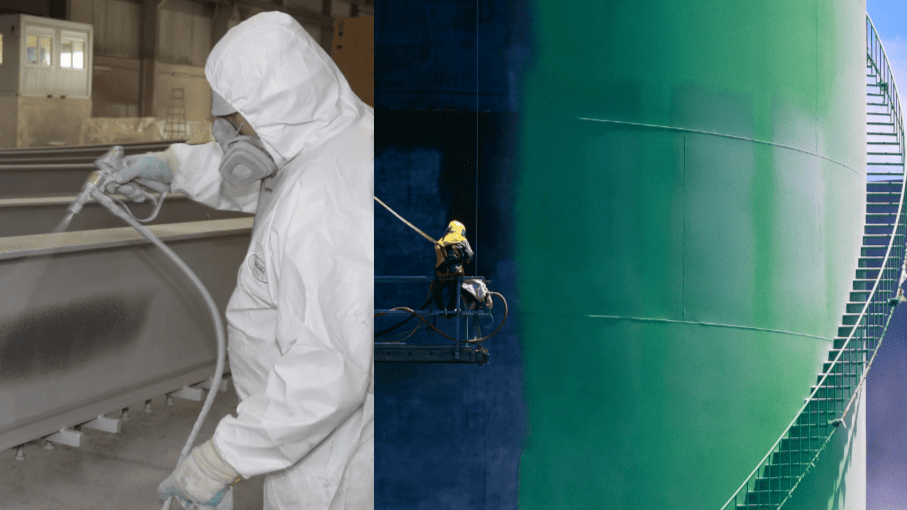

Protecting Your Assets from Corrosion

Our industrial blasting and painting services are meticulously designed to prepare and protect surfaces in challenging industrial settings. We ensure longevity and durability for your vital infrastructure through specialized preparation and coating techniques.

The protection process:

- Surface Preparation

We employ advanced techniques to remove contaminants and create a perfectly clean surface ready for coating, ensuring maximum adhesion and longevity:

- Sand Blasting

A versatile method using abrasive media to strip old coatings and rust, ideal for general industrial applications.

- Captive Blasting

A dust-free system for concrete and steel floors, collecting debris instantly and making it suitable for sensitive environments.

- Automatic Shot Blasting

High-efficiency, automated blasting used for large-scale steel components, ensuring consistent and rapid surface profiling.

- Protective Coating Application

Our painting services include applying high-grade industrial coatings tailored to the specific environment:

- Protective Coating

Applying robust layers such as epoxy and polyurethane to prevent corrosion and withstand harsh industrial environments.

- Marine Coating

Utilizing specialized marine-grade paints designed for extreme exposure to saltwater and harsh weather conditions.

- Decorative Coating

Applying finishes that enhance the aesthetic appeal of structures while still offering durable protection.

Safeguarding Structures from Fire Hazards

We offer comprehensive industrial fireproofing services to protect your vital assets and ensure the safety of your facility. Our tailored solutions are designed to achieve essential fire resistance ratings (FRR) as per stringent regulatory standards, providing critical peace of mind and full compliance.

Our specialized fireproofing approach:

- Application Methods

We apply advanced fireproofing solutions designed to safeguard structures and equipment from extreme thermal hazards:

- Epoxy Intumescent Coating - Hydrocarbon and Jet Fire

A high-performance, durable coating specifically engineered to protect critical infrastructure in the oil & gas and energy sectors from severe, rapid-onset hydrocarbon pool fires and high-velocity jet fires.

- Intumescent Fireproofing - Cellulose Fire

A reactive coating that expands significantly when exposed to the heat of a standard building (cellulose) fire, forming an insulating char layer to protect steel and concrete structures.

- Cementitious Fireproofing

A robust, cost-effective spray-applied fireproofing material (often referred to as “hard fireproofing”) used to provide durable thermal barriers and achieve high fire resistance ratings in industrial and commercial environments.

Durable and Safe Solutions for Industrial Floors

Enhance the durability, safety, and aesthetics of your industrial floors with our specialized coating services. We provide resilient surfaces ideal for manufacturing facilities, warehouses, and commercial spaces.

Our floor coating solutions:

- Preparation & Application

We ensure meticulous surface preparation—including professional Floor Grinding—followed by expert application of high-performance coating systems:

- Floor Grinding

Essential mechanical preparation of concrete substrates to ensure a clean, level surface profile for optimal coating adhesion and longevity.

- Epoxy Floor Coating

A tough, resilient coating offering superior resistance to chemicals, abrasion, and heavy foot traffic, ideal for general manufacturing areas.

- Self-levelling Floor Coating

A smooth, seamless application used to restore damaged concrete floors, creating an extremely flat and aesthetically pleasing surface that is easy to clean.

- PU Crete Floor Coating

A heavy-duty polyurethane concrete system designed for extreme thermal shock, impact, and chemical resistance, commonly used in food processing and beverage industries.

- Anti-Static Floor Coating

Specialized coatings designed to control electrostatic discharge (ESD) in sensitive areas like data centers, laboratories, and electronics manufacturing, protecting sensitive equipment.

Ensuring Longevity and Durability of Structures

Our specialized waterproofing applications:

- Steel Roof Waterproofing

We apply specialized coatings and high-performance membranes to steel roofs to prevent water ingress, halt rust formation, and mitigate structural damage. Our systems ensure a durable, watertight roof that extends the lifespan of your facility.

- Concrete Waterproofing

We protect exposed concrete surfaces and sub-structures from moisture penetration, chemical exposure, and environmental deterioration. We utilize robust sealants, flexible coatings, and membranes to safeguard foundations, reservoirs, and process areas, ensuring asset integrity.

Maximizing Uptime Through Proactive

Our maintenance strategies include:

- Preventive Maintenance (PM)

We implement scheduled inspections, routine servicing, and timely repairs to prevent equipment breakdowns before they occur. This proactive approach identifies potential issues early, mitigating the risk of unplanned downtime.

- Predictive Maintenance (PdM)

Utilizing data-driven techniques such as condition monitoring, vibration analysis, and thermal imaging, we anticipate equipment failures. Analyzing performance indicators allows for targeted interventions that prevent costly breakdowns.

- Routine Inspections

Our teams conduct regular visual inspections and testing of equipment and systems to identify early signs of wear, damage, or deterioration, ensuring timely replacement of components before critical failure.

- Equipment Calibration

We provide essential calibration of instruments and control systems to ensure accuracy and reliability in monitoring critical process parameters, maintaining product quality, safety, and regulatory compliance

The Right Expertise for Your Specialized Projects

We cover the entire spectrum of staffing needs:

- Specialized Staffing

We source and provide qualified candidates for specific roles, including Skilled Engineers, QA/QC Inspectors, HSE (Health & Safety Environment) Professionals, and ARAMCO Certified Professionals.

- Recruitment and Placement

Our rigorous process involves conducting job analyses, screening resumes, interviewing candidates, and facilitating seamless placement of qualified personnel tailored to your organizational needs.

Flexible Access to Essential Machinery and Transport

Our diverse inventory includes:

- Equipment Rental

We provide a wide selection of heavy machinery tailored for the civil and industrial sectors, including excavators, bulldozers, cranes, generators, aerial lifts, and specialized tools to meet project demands

- Transportation & Logistics

Provision of essential trucks and vehicles to support site logistics and project transportation needs, ensuring efficiency across all operations.

Start Powering Progress Today

Join the specialists who are shaping industrial landscapes and delivering resilient infrastructure for the next generation.

Why Choose Us

We manage the complexities of industrial contracting with integrity and expertise. We deliver projects that exceed expectations in high-stakes environments.

01

Trusted Specialist

Skilled engineers, ARAMCO-certified professionals, and trade specialists with deep sector expertise.

02

Quality & Safety Certified

03

Client Partnership

Transparent communication, reliable project management, and a focus on building long-term client trust.

Frequently Asked Questions

How long does it take to complete a typical industrial or civil construction project?

The timeline depends entirely on the project’s complexity, scope, and regulatory requirements. Smaller civil works may be completed in months, while large-scale energy infrastructure projects often span 1 to 3 years. We provide clear, critical path schedules during the planning phase.

Do you prioritize sustainability and safety in your construction methodologies?

Can you assist with necessary permits, regulatory compliance, and certifications?

Absolutely. Our experienced team assists clients with navigating all necessary documentation, project permits, and compliance requirements, including specialized certifications needed for industrial sectors like oil & gas (e.g., ARAMCO certifications).